SUBSA Implementation Partner

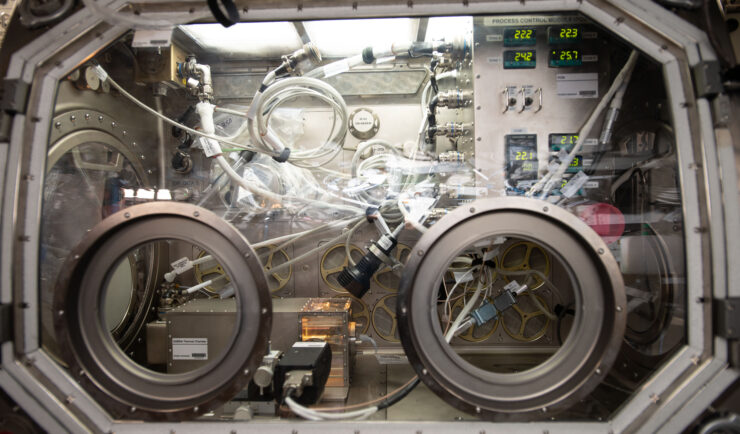

SUBSA (Solidification Using a Baffle in Sealed Ampoules) SUBSA is a high-temperature furnace on the International Space Station (ISS) that melts materials at a controlled rate, holds at maximum temperature to stabilize, and then solidifies at a precise cooling rate via a gradient freeze technique in a microgravity environment. A transparent zone in SUBSA enables…

Construction and management of emergency housing solutions

Providing Emergency Housing and Base Camp Services for Government, and Private Companies nationwide. About this Partnership CSS has formed a strategic partnership with GFP Response, a premier emergency response solution provider. GFP is a premier emergency response solution provider. Services include emergency mobile services, specializing in base camp solutions and emergency management. Our partnership with GFP…

Coastal Aquaculture Program / Coastal Aquaculture Siting & Sustainability Program

CSS supports the NCCOS mission to provide high quality science, guidance, and technical support to coastal managers to grow sustainable aquaculture while maintaining and improving ecosystem health.

Network Engineering Design and Support

CSS engineers and deploys large-scale networks to support multi-campus and multi-facility environments.

Custom Software Engineering

CSS develops customized software solutions for NASA life sciences and energy management.

Managed Desktop Services

CSS designed, implemented, and provides ongoing support of a complex virtual desktop and server infrastructure for Space Florida.

Pacific Ecological Services Division Project (PESD)

Since 1996 CSS has conducted field and lab-based research in support of the Pacific Ecological Services Division Project

Evaluation of Pesticide Safety

CSS supports the EPA Office of Pesticide Programs in evaluating the safety and potential health and environmental risks resulting from the use of pesticides and ensures that the data utilized for EPA’s regulatory decisions are scientifically sound.

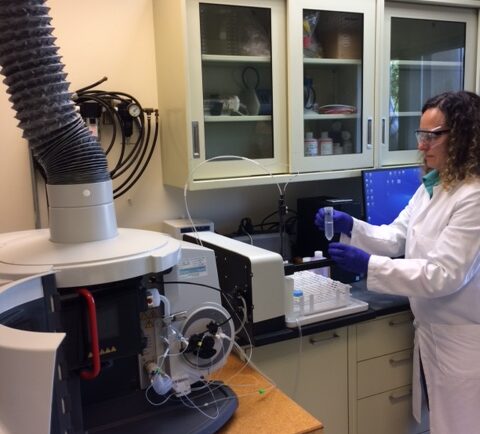

Analytical Chemistry Support for the US EPA National Aquatic Resource Survey

CSS chemically analyzes hundreds of water samples collected annually from the US EPA’s National Aquatic Resource Survey (NARS), a critical contribution to the EPA assessments of the condition of the nation’s water bodies.